HLA is one of the most sought after engineering firms in the industry when it comes to forensic analysis and design of industrial structures. Most notably, HLA was called in to examine and analyze the collapse of the Hoover Dam Bypass Bridge construction collapse. Assignments like these, small or large, are welcomed with equal enthusiasm.

Cranes and Craneways — Tower, gantry, top running and underhung cranes; analysis and modifications of all types of materials handling equipment.

Heavy Industrial Equipment — Press frames; compressor and generator skid mounted units; jigs & fixtures; foundation design.

Mining Equipment — ROPS/FOPS guards, dump bodies, fatigue and fracture evaluations.

Industrial Buildings — Design and analysis; building evaluations and modifications; craneways and craneway modifications; foundations. All materials – steel, concrete and wood.

Failure Analysis — Civil, process and industrial structures; computer simulation; impact simulation.

Selective Catalytic Reduction Systems (SCR)

Selective Catalytic Reduction Systems (SCR)

HLA provides a full range of engineering services for SCR such as:

Detailed duct design from turbine exhaust to stack outlet foundation design interface coordination and design

All building codes for seismic and wind

UBC, CBC, BOCA, SBC, ASCE, AISC, etc

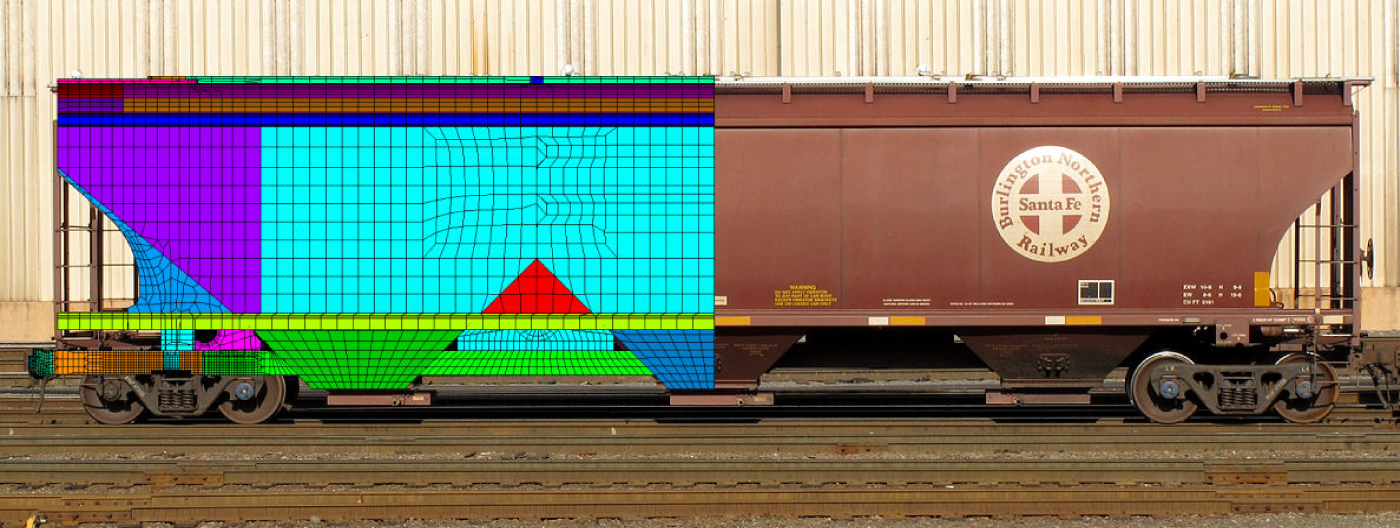

HLA Engineers, Inc., is considered one of the foremost authorities on railcar design and analysis in the world. As such, HLA maintains a unique “feel” for car structure, and an in-depth understanding of the industry as a whole. HLA’s team of engineers are acquainted with key personnel at both AAR and DOT, and are familiar with the governing codes throughout the United States as well as many other countries

HLA performed the first finite element analysis of a railcar in 1972 when they analyzed and assisted in the redesign of the 5800 cu.ft. plastic pellet car. HLA Engineers has designed or participated in the design and analysis of literally every type of railcar manufactured today, including:

HLA Engineers has designed or participated in the design and analysis of literally every type of railcar manufactured today, including:

High side gondola

Maintenance of Way Cars

Box car

Flat cars, bulkhead flat

Pulp wood

Plastic pellet

Pressure differential

Tank and cryogenic tank car

Inter-modal articulated well, stand-alone well, and spine cars

Open top and covered hopper cars (both stub and thru sill)

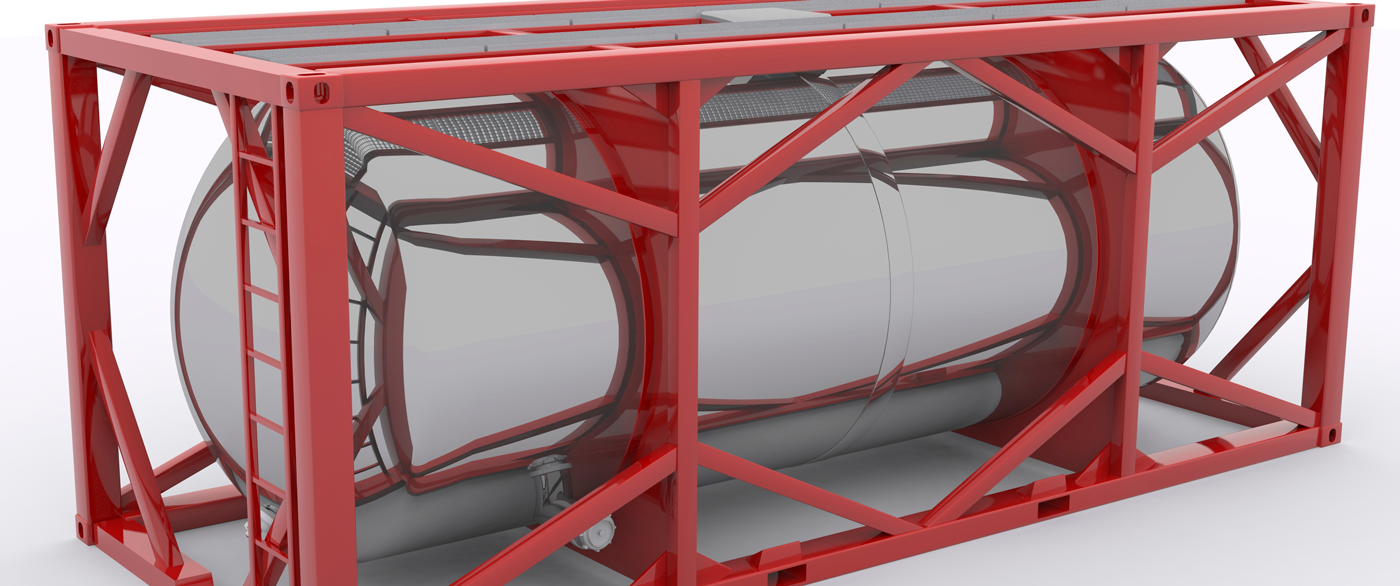

HLA Engineers has performed dry cargo container design and analysis, tank container design and stress analysis (minimum weight design and testing). ISO tank containers (UN Portable Tank, DOT Spec 51, IM01, IM02 and IM05) for liquefied gases, industrial chemicals and food products. We have also designed and drafted ISO refrigerated and non-refrigerated freight containers to DOD standards.

HLA has extensive experience with verified compliance and international shipping codes (IMDG, RID, ADR, etc.) and has performed liaison work with certification agencies (American Bureau of Shipping and Lloyd’s of London and Bureau Veritas).

HLA manages physical testing of containers to ISO standards and has been engaged by the international trade organization, IICL, to determine the effects of damage on ISO shipping containers including combined finite element analysis and a test laboratory analysis to establish damage criteria.

Our Experience includes:

Containers — Designed, analyzed and tested ISO tank containers and dry cargo containers, 20 and 40 foot.

Chassis — Designed truck trailer chassis for containers: 20, 40 and 45 foot.

Chlorine Ton Containers — Designed / drafted chlorine ton containers per DOT 106A and 110A specs. Also designed stacking frame for shipping / storage.

HLA Engineers has extensive petrochemical engineering experience and has solicited turnkey projects in design, analysis and testing, as well as troubleshooting and special problem solving. Teaming with local consultants for process, electrical and controls, HLA can provide complete engineering of new, remodeled or retrofitted oil and chemical production, refinery and on offshore projects.

HLA provides the following:

Pressure Vessels

Horizontal, vertical and spherical, including skirts, columns and/or saddles

ASME Code Section VIII Division 1 and Division 2 rules

Fabrication drawings and calculations for all types of Division 1 pressure vessels and storage tank facilities: carbon and stainless steel, exotic materials (Hastelloy, Monel, composites); cladding; autofrettage

Engineered, analyzed and drafted fabrication drawings for many high pressure cryogenic vessels: to 10,000 psi and –423F, per Division 2 in Seismic Zone 4 and rail transportation

Computer analysis and simulation of quick opening closures (to 36″ diameter)

Computer analysis of piping pressure sensors and flow meters

Piping

Design and analysis: B31.1 and 31.4. pipe racks, valve design and analysis, special fitting analysis, thermal, seismic, water hammer, flexibility/stress analysis, hangers and supports: vibrations/seismic, thermal loads.

Spherical laminated piping flex joints, computer analysis of piping pressure sensors and flow meters.

Storage Tanks

API 650 and API 620, structurally supported and self supporting roofs

Off-shore Oil Platform Mooring Systems

Drilling Rigs

Sequence Effects, Truncation, Clipping, Retardation

Marine Risers

Modal, Harmonic PSD random and Seismic vibration

Compressors

S-N Curves, Endurance Limit and Fatigue Strength Surface & Size effects

Drilling Components

Data, Load Streamlines Analogy

Failure Analysis

HLA Engineers can perform design and analysis of structures of polymer matrix composites with both thermoset and thermoplastic resin systems and other matrix materials and smart structures. Our experience includes:

Determination of elastic moduli

Determination of strength in brittle matrices

Compression behavior

Effect of orientation on elastic properties

Simple laminates and the approximation of the properties of woven and random fiber composites

Sandwich core composite structures well, and spine cars

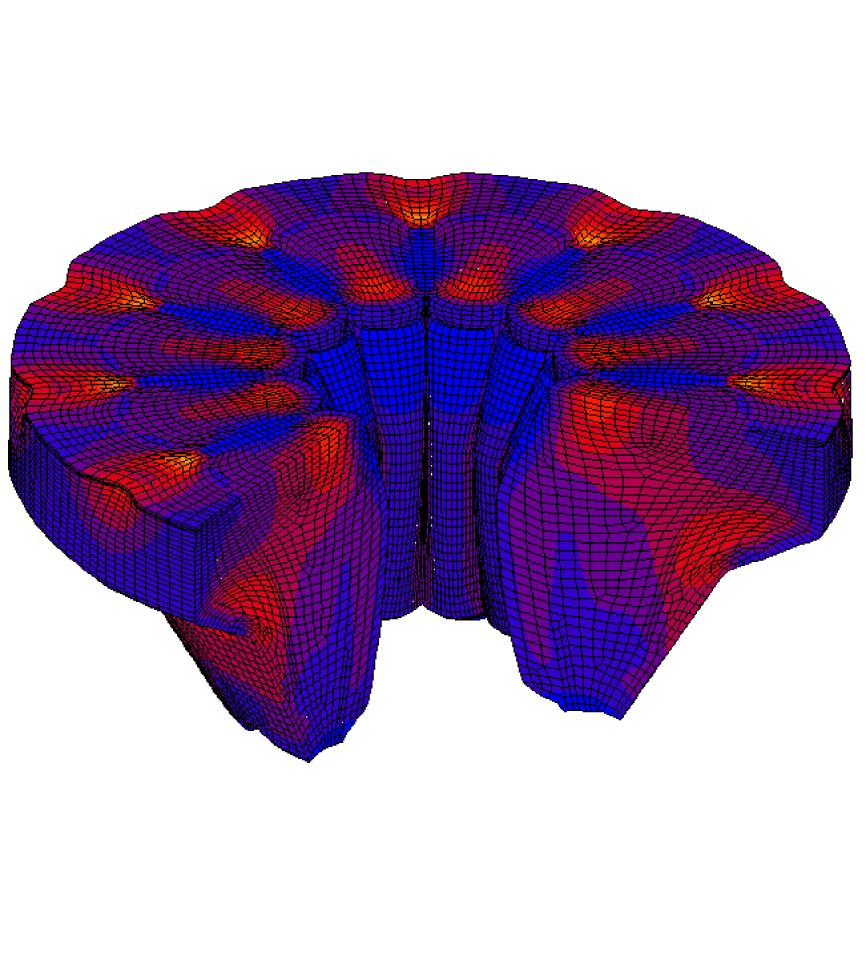

Stress Analysis

Extensive FEA Experience with ANSYS and LS-DYNA

2D/3D and Quasi-3D FEA in stress analysis

Material and geometric nonlinear analyses

HyperElastics and HyperElastic composites

Failure criteria and failure modes

Laminate strength and strength theories

Residual stresses, stress concentrations, and interlaminar stresses

Laminate progressive failure

Failure theories including max stress, max strain, and quad

Failure criteria such as Tsai-Wu, Hoffman, and Hill

Composite delamination, edge delamination effects, design and analysis

Fatigue and linear elastic fracture mechanics, toughness in composites

Thermal and hygrothermal analysis, TMA, TGA and DSC of polymeric materials

Optimization of material propertieas of composites and sensitivity analysis

Experimental characterization of composites and physical testing

For over 40 years HLA has strived to be the industry leader providing complete design and stress analysis for all types of trailers including, but not limited to: DOT MC 331, 338, 406, 407, 412 cargo trailers and LPG, NH3, CO2, chlorine and cryogenic transports.

HLA performed the first finite element analysis of a railcar in 1972 when they analyzed and assisted in the redesign of the 5800 cu.ft. plastic pellet car. HLA Engineers has designed or participated in the design and analysis of literally every type of railcar manufactured today, including:

HLA has also performed design and analysis of ASME pressure vessels (Section VIII, Divisions 1 and 2), cryogenic pressure vessels, ISO intermodal tank and dry cargo containers, MC 331 transports and many other types of transportation equipment.

Containers — Designed, analyzed and tested ISO tank containers and dry cargo containers, 20 and 40 foot.

Chassis — Designed truck trailer chassis for containers: 20, 40 and 45 foot.

Chlorine Ton Containers — Designed and drafted chlorine ton containers per DOT 106A and 110A specs. Also designed stacking frame for shipping / storage.

Cargo Transport Trailers — Design and analysis; building evaluations and modifications; craneways and craneway modifications; foundations. All materials – steel, concrete and wood.

Failure Analysis — HLA provides complete design and stress analysis for DOT MC331, 338, 406, 407, 412 LPG, anhydrous ammonia, carbon dioxide and chlorine transport trailers: semi and bobtail and cryogenic transports. We have analyzed and verified design load

HLA has a long history of performing the necessary design and engineering and forensic engineering of Finite Element Programs, 2D, 3D, Psuedo-3D, Hyper-realistic and special purpose engineering. Our engineering experts can help you with design programs for:

Aircraft

Railcar analysis

Engineering mechanics

Mechanical

Structural

Civil

FRP and elastomers

Fatigue

Fracture mechanics

Existing program modifications / improvement

Graphical user interfaces

Program adaptions

Machines